The Prestige Dynamics Industries Sdn. Bhd. Quality Assurance Program stems around our Quality Policy statement: Prestige Dynamics Industries Sdn. Bhd. Is fully committed to develop employee’s capability and improve continually in making quality and cost effective products that exceed customer expectation.

In order to achieve or ambitious vision,

we set the following objectives:-

-To achieve total customer satisfaction through continual improvement in quality.

-To apply ISO/TS16949 Quality Management in improving all aspect of the company.

-To become the preferred supplier of our customers.

The management and staff at Prestige Dynamics Industries Sdn. Bhd. are continuously reviewing, improving upon and documenting the quality practices and standards of our operation. We strive to provide products and services that consistently meet or exceed our customer requirements and with the following clarification:-

-ISO 9001:2008 (Certificate No. : 44 100 060797)

-ISO/TS16949:2009 (Certificate No. : 44 111 060797)

-ISO 14001:2004 (Certificate No. : 44 104 082263)

-ISO 13485:2012 (Certificate No. : 58281/A/0001/UK/En)

-Underwriter’s Laboratory (UL) certified (UL Registered No. : E201057-1)

Read More

The Quality Assurance Manager administers Prestige Dynamics Industries Sdn. Bhd. Quality Management System. The manager’s primary responsibility is implementing and evaluating all quality assurance policies and procedures outlined in the Prestige Dynamics Industries Sdn. Bhd. quality manual. In addition, the quality manager provides on-going evidence of compliance with all policies, procedures and inspection plan and work instruction. At the direction of the quality assurance manager, internal quality audits and the retention of records provide a systematic basis to ensure compliance monitoring. As to achieve customer requirements and to fulfill ISO/TS 16949, ISO13485 and ISO14001 requirement, we have perform yearly system audit, manufacturing process audit, product audit and layout inspection for maintaining quality management system and to maintain the quality of products.

First piece buy-off, last piece buy-off, incoming inspection, 2 hourly in-process inspection and outgoing inspection with acceptance quality limit ( AQL) – 0.4, C=0 used as a gate of quality to detect error or reject during incoming, production and before send finished products to customer .

Other than that, we utilize variety of following quality tools to resolve issues related to quality:-

-Failure Mode and Effects Analysis (FMEA)

-Process Control Plan – for individual product, secondary process and assembly

-Statistical Process Control (SPC)

-7 QC Tools for problem analysis

-8-D Corrective Action

-Measuring System Analysis (MSA) – including GR&R, bias, linearity and stability

-Process Capability Study (CPK)

-Problem Solving Sheet (PSS)

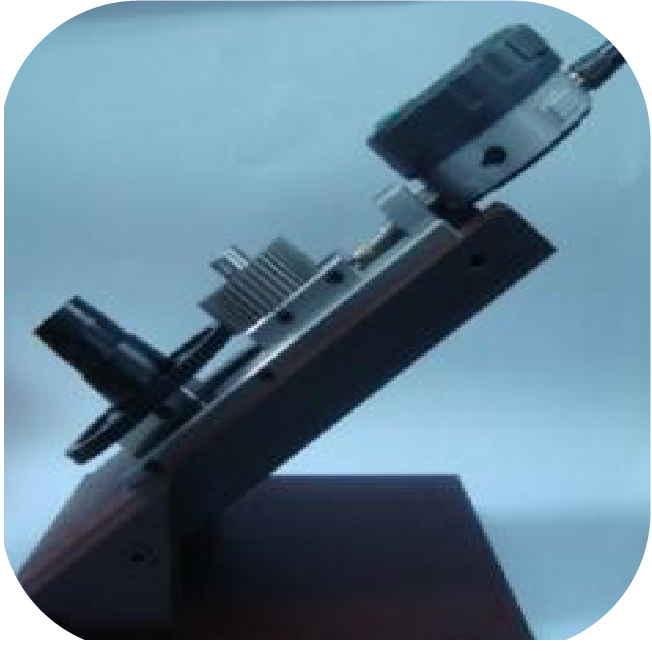

Prestige Dynamics Industries Sdn. Bhd. Quality Assurance is proud to offer its accumulated experience through advance product with established a metrology lab with modern equipments run by qualified staff including:-

High Performance CMM with laser scanning facilities

OGP Non-Contact Smart scope

Spectrophotometer (use for colour measurement) Surf test

Height Gauge

Gear checker

Small tool equipments including caliper, pin gauge, dial & digital indicator and etc.