Advanced Tooling & Quality Verification

Precision-Driven Development Areas

From concept to execution, we focus on excellence in every aspect of our specialized fields.

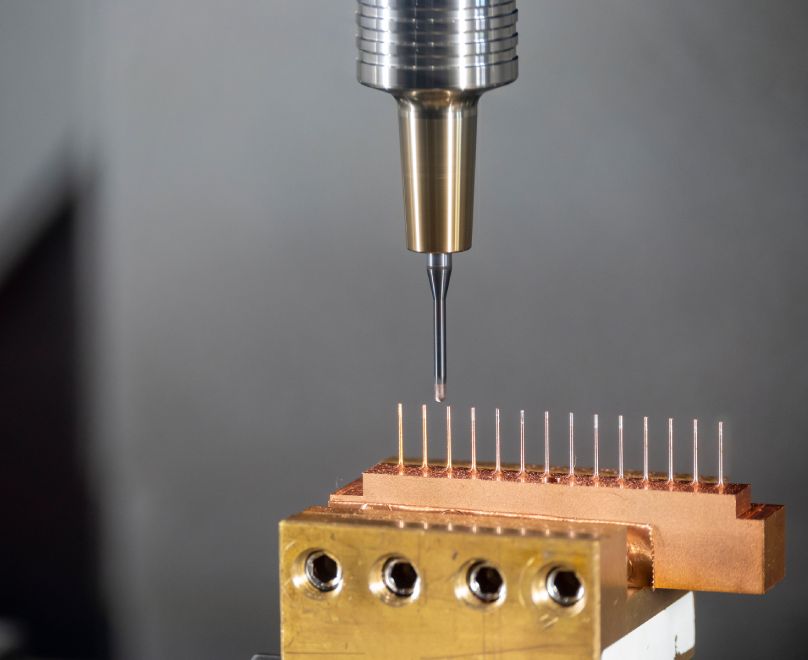

Precision Tooling Expertise & Lifetime Performance

Integrated Tooling Capabilities

From concept to completion, Prestige Dynamics Industries applies precision engineering and advanced manufacturing practices to build molds that deliver performance, reliability, and longevity. Our integrated tooling capability ensures alignment between design intent, manufacturing precision, and production efficiency.

Design and Simulation

High Precision Machining

Hot Runner and Cooling Integration

Each mold is equipped with optimized cooling channels and hot runner systems from leading global suppliers to maintain temperature uniformity, reduce material waste, and ensure consistent part formation.

Mold Validation and Testing

Maintenance and Lifetime Support

From design to production — precision engineered for lifetime reliability.

Each tooling project follows a structured design and validation framework to ensure precision and repeatability from machining to mass production. This process is supported by dimensional inspection, heat treatment verification, and functional mold trials to confirm part quality and performance stability. By integrating design, simulation, machining, and testing within one facility, we reduce lead times, strengthen quality assurance, and maintain traceability across the entire tooling lifecycle.

We work closely with customers to co-develop tool designs that optimize manufacturability, minimize rework, and deliver long term reliability. This collaborative approach enhances production efficiency and ensures every mold performs to specification throughout its operational life.

Our tooling team also focuses on continuous improvement through material innovation, process refinement, and preventive maintenance programs that maximize uptime and extend tool service life. Every precision mold we build represents our commitment to consistency, accuracy, and lasting performance across automotive, electronics, medical, power tools, IoT, and industrial applications.

Success Stories

Success Story 1

Cycle Time Reduction Through Scientific Moulding Optimization

Our R&D team conducted a full 14-segment scientific moulding optimization for a high-volume product line. As a result, we reduced the overall cycle time by 18%, while maintaining stable product quality. This led to a 12% increase in production efficiency and significant energy savings—delivering measurable cost benefits for the client.

Success Story 2

Extending Mould Life with Precision Parameter Tuning

By applying our advanced moulding parameter optimization framework, we identified stress points affecting mould longevity. Adjustments to pressure, cooling time, and injection velocity extended the tool life by 25%, reducing maintenance downtime and increasing the number of production shots per mould.

Success Story 3

Improving Machine Utilization with Data-Driven Optimization

One of our clients faced inconsistent output due to parameter drift. Our R&D engineers used optimization data to fine-tune machine settings and monitor key variables. As a result, machine utilization improved by 22%, product rejection rate dropped by 40%, and process repeatability was achieved across multiple shifts.

Built for Performance