As a trusted partner in the automotive industry, Prestige Dynamics Industries provides advanced plastic solutions designed for demanding performance, safety, and durability requirements. We support OEMs and Tier 1 suppliers with complete lifecycle services, from development to mass production, across powertrain, interior, exterior, lighting, and electronic modules.

Our R&D team works with automotive grade materials such as engineering plastics and specialty blends, using simulation tools for flow, warpage, and mold cooling to optimize designs for crash, thermal, and fatigue performance.

For tooling, we produce high precision molds including 2 plate, 3 plate, 2K, vertical, and unscrewing types, built to withstand millions of cycles under tight dimensional tolerances.

Our injection molding capabilities include multi shot, insert, and overmoulding processes essential for modern automotive modules such as sensors, connectors, and housings.

Secondary processes like laser marking, pad printing, and ultrasonic welding provide branding, traceability, and assembly readiness. Final assembly and measurement ensure every module meets strict tolerances, functional testing, and automotive quality standards such as PPAP and FAI.

We understand the rigorous requirements of automotive compliance, durability under vibration, temperature extremes, chemical exposure, and long service life. Each component is validated through capability studies (CpK/CmK), dimensional inspection, and lifecycle testing. Over the years, we have supported leading automotive brands with reliable, high volume part production.

Looking ahead, we are focusing on electrification and autonomous vehicle systems. Our expertise in multi material molding, sensor housings, thermal management components, and integrated electronics has positioned us to support the next generation of automotive innovation.

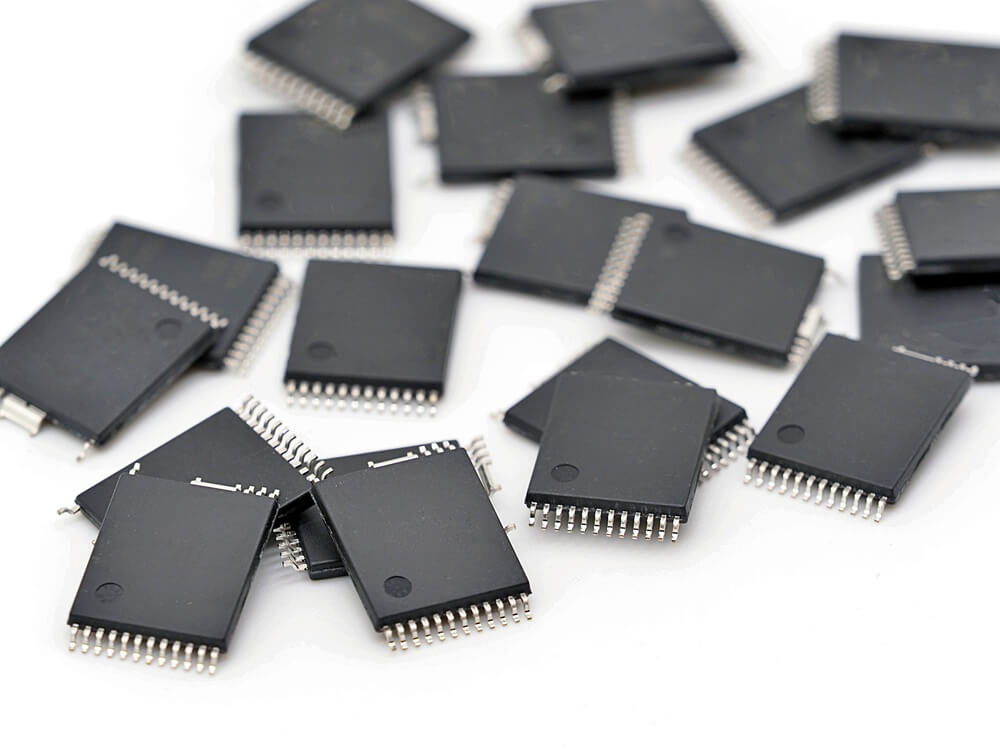

In the fast-paced electronics sector, components demand miniaturization, precision, and stability. Prestige Dynamics Industries is equipped to deliver plastic parts, connectors, insulators, housings, and modules that meet stringent electrical, thermal, and aesthetic requirements.

Our R&D work includes simulation to predict field shrinkage, clearance between mating parts, and tolerance stack ups, which are vital when dealing with micro connectors or tight-fitting enclosures. Tooling fabrication ensures ultra precise molds with consistent gate design, runner balance, and optical surface quality. Injection molding lines handle small, high precision parts with tight tolerances.

Secondary processes such as laser marking, pad printing, and ultrasonic welding enhance the functionality and durability of electronic assemblies. Our assembly operations integrate components including PCBs, connectors, and sensors, while measurement services provide CMM inspection, surface profiling, and functional testing to ensure fit and performance.

As electronics continue to evolve, including 5G, mini IoT devices, and embedded sensors, we continue investing in precision optics compatible plastics and the integration of electronics with plastic structures, positioning ourselves as the bridge between mechanical and electronic design.

The IoT and technology sector demands flexibility, connectivity, and intelligent integration. Prestige Dynamics Industries supports products such as smart sensors, wearable devices, communication modules, and consumer electronics that require compact, high performance plastic enclosures and subassemblies.

From R&D to prototyping, we help design enclosures with embedded clips, snap fits, vents, and antenna windows to ensure signal integrity and manufacturability. Tooling is often multi cavities and designed for modular inserts or overmoulding of conductive materials.

Our injection molding capabilities cover both rigid and soft touch plastics, supporting hybrid parts that combine rigid and elastomeric materials through two color injections.

We help clients shorten product development cycles by providing not only manufacturing but also design for manufacturability feedback, mini batch pilot runs, and scalable transitions to high volume production. Our quality systems and traceability frameworks ensure consistency and accountability in fast-changing product environments.

In a technology driven world, we continue to explore materials that improve durability, miniaturization, IoT encapsulation, and low power embedded designs. Our combined expertise in electronics, plastics, and assembly positions us to support emerging technologies with precision and confidence.

Prestige Dynamics Industries manufactures critical components such as housings, connectors, valves, inhalers, diagnostic device parts, and surgical instrument carriers that meet ISO 13485 standards and strict validation requirements.

Our R&D team ensures each design is optimized for chemical resistance, tight tolerances, and clean molding performance. Flow simulation is conducted to prevent sink marks and internal voids, which is vital in fluidic or medical grade components.

Tooling is produced using high quality tool steels verified for cleanliness and finished to mirror standards for tight tolerance applications. Injection molding operations are carried out in controlled or cleanroom environments with rigorous process control, traceability, and documentation.

We supply to OEMs in medical devices, life sciences, and diagnostics, with strong emphasis on risk management, documentation, and compliance. Our full traceability, FAI reporting, and capability studies provide confidence during audits and regulatory submission.

Looking ahead, we are expanding into microfluidics, lab on chip components, biocompatible coatings, and integrated sensor modules to support the next generation of medical device innovation.

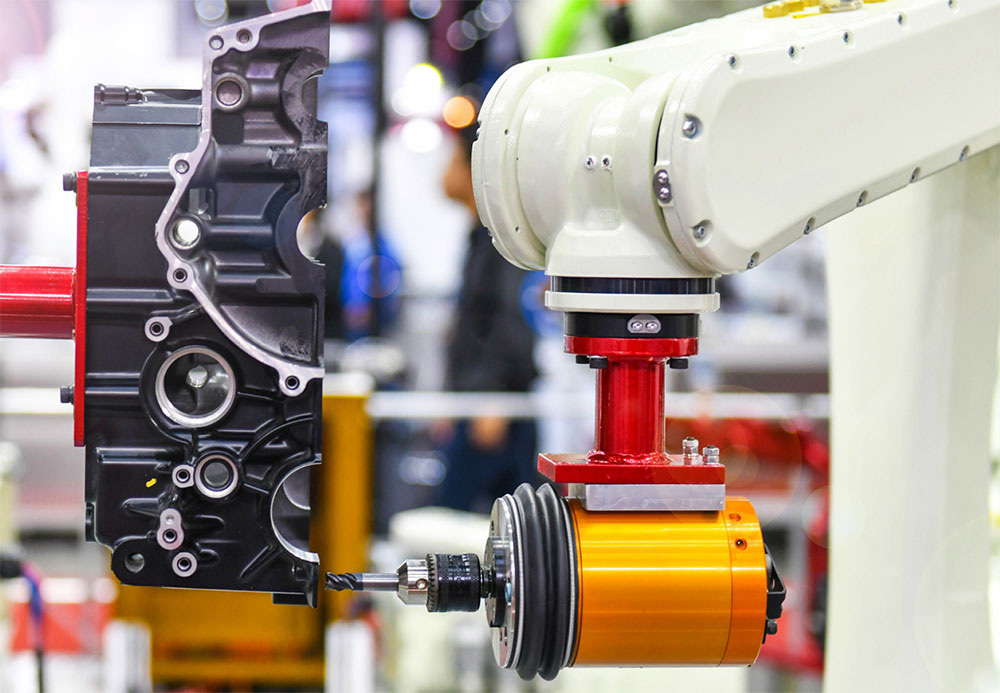

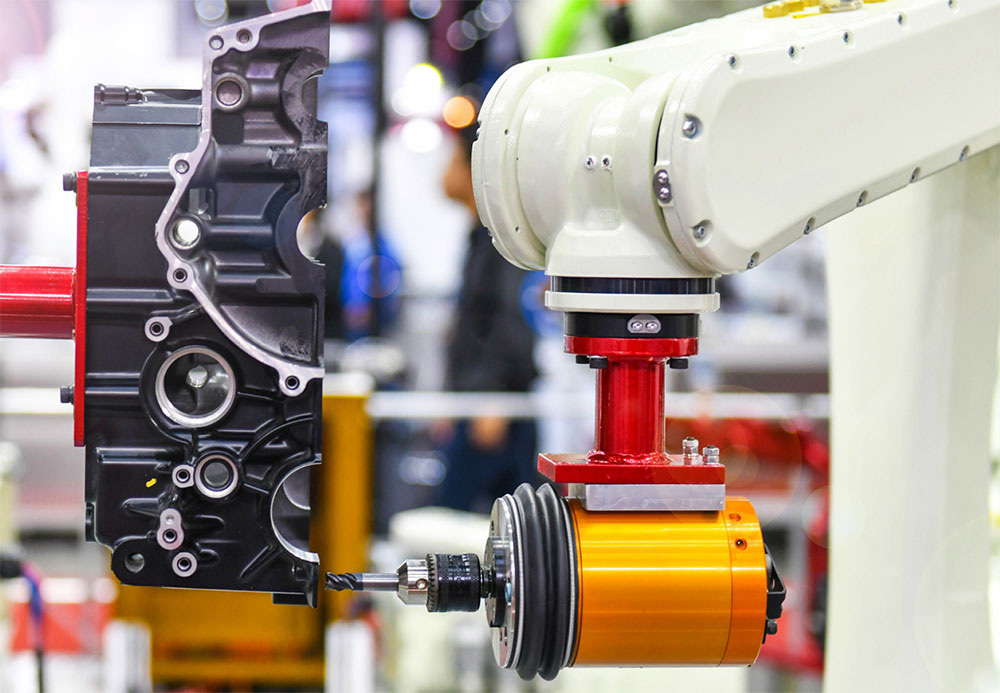

Prestige Dynamics Industries supports the power tools sector with rugged, high performance plastic components designed for durability, impact resistance, and ergonomic comfort. We manufacture housings, handles, and modular enclosures for drills, grinders, and other portable equipment that must perform reliably under demanding conditions.

Our R&D team works closely with customers to enhance grip ergonomics, vibration control, airflow management, and cooling efficiency while ensuring manufacturability and structural integrity. A key capability is two material molding, where rigid structural substrates are combined with soft touch surfaces to improve comfort, insulation, sealing, and impact resistance. This approach allows seamless transitions between materials, creating parts that are both robust and user friendly while reducing secondary assembly operations.

Tooling is developed for thick wall, glass fiber reinforced engineering plastics and two material configurations, focusing on stiffness, dimensional stability, cooling balance, and process repeatability. Injection molding operations handle materials such as nylon, PC ABS, TPE, and reinforced compounds with precise temperature control and consistent shot to shot performance.

Secondary processes include pad printing, screen printing, laser etching, and ultrasonic welding for inserts, fasteners, and decorative details. Assembly operations integrate motors, switches, gears, sensors, and wiring, followed by functional testing for torque, speed, vibration, and endurance.

Measurement services verify clearances, concentricity, and dimensional accuracy within strict tolerances. We add value through design optimization, failure mode evaluation, long term reliability testing, and process feedback throughout product development and validation.

Our integrated assembly and inspection systems ensure every component meets safety, performance, and compliance standards before shipment. As the power tools industry continues to evolve, we are investing in two material housings, smart connectivity, modular designs, and sustainable materials to support the next generation of advanced tools with precision and reliability.