Core Capabilities

Scientific Moulding process optimization:

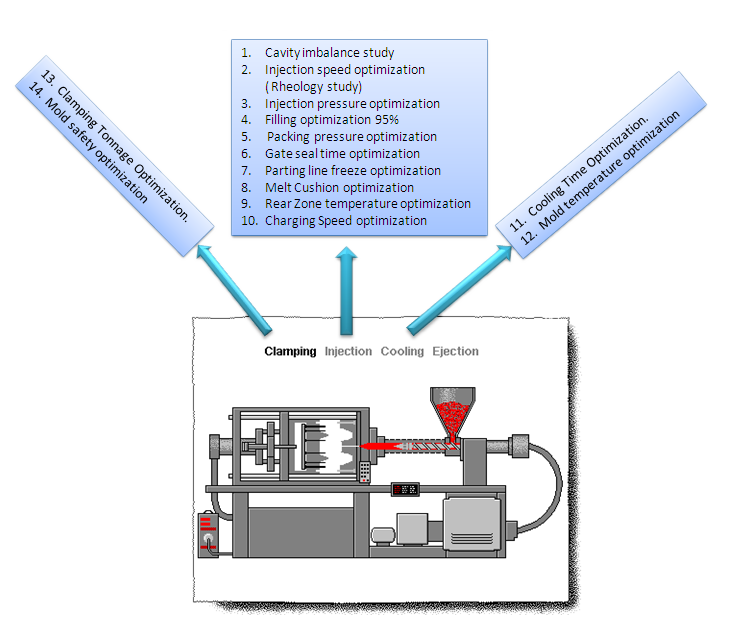

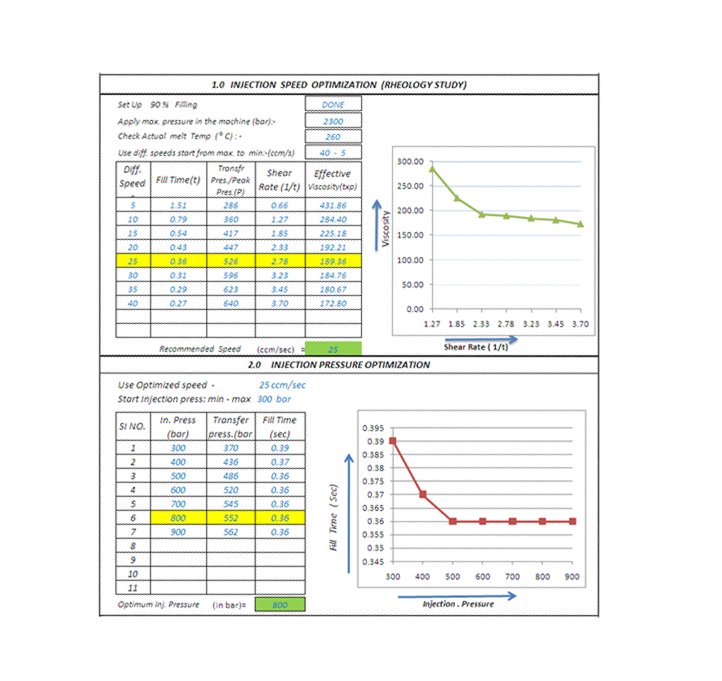

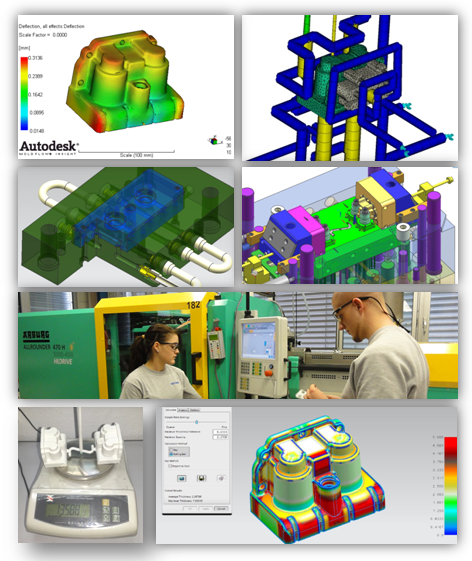

PDI is equipped with an advanced team of talented Process Engineers who had undergone on hand training in “advanced scientific moulding optimization” which is conducted by Routsis training-USA. The right optimum moulding parameters can be identified & documented through conducting a scientific optimization. Optimization process will be conducted a total of 14 different segments of overall injection moulding cycle to identify the optimum values of moulding parameters. These optimized parameters will ensure a robust moulding process which results stable product quality, lesser energy consumption level, improved cycle time, optimum utilization of machine resources, process-safety and longer life of moulds & machine etc. A proper optimization results also will give better clarity on the accuracy of the machine & room for improvements. An efficient Monitoring of product quality can be achieved through proper documentation of the optimized parameters

Optimization Segments