PDI Business Solution?

PDI provides integrated solution for our customers, a one-stop solution provider.

Early Involvement & Product Development

PDI can become involved in a product’s life cycle as early as initial concept development, where we literally become an extension of our customer’s product development team. We are accustomed to working with a wide variety of CAD data, drawings, or even ideas in the sketch stage.

PDI recognizes that many companies have limited resources and budget constraints for developing new products. Additionally, some have limited plastics injection molding and tooling experience. This is where PDI can fill the gap. PDI excels at Product Development and Design for Manufacturability (DFM) support. We are strong believers that early supplier involvement is critical to successful new product introductions. The goal is to reduce customer product cost and time-to-market.

Free Initial Consultation

When you contact us via email, phone or in person, we’ll provide a free expert consultation. If you require a non-disclosure agreement, we’ll be happy to sign one. PDI clients can be confident that their proprietary information is protected while in our custody. With the experience PDI have in plastic industry, we are able to provide you our expertise in part design, tooling design, part manufacturability and as well as material selection.

Moulding Material

PDI utilize the most advanced injection molding technology to process a wide variety of thermoplastic materials. We are fully equipped to mold the most challenging thermoplastic materials. The science and engineering that goes into producing high quality injection molding components has become increasingly more technical. Having the right equipment is only half of the equation to making consistently good product. A well-educated and highly trained workforce is the other half. Most of our process engineers are well versed with all elements of injection molding process validations.

With our experience comes an expertise in molding both commodity and engineering grade plastic materials. From high heat Polyether ether ketone (PEEK) to medical grade Polypropylene (PP), PDI can process nearly all commodity and engineering grade plastic materials available today.

PDI is experienced in handling colored plastic resin, from Red, Yellow, Blue or even special custom color plastic resin material. We have liaised with our reliable supplier for color compounding, master batches, pre-mix & pigmentation. PDI is experienced in producing Clear parts, such as Light guide. Having our controlled manufacturing room, Clear part will not be an issue.

Precision Tooling

PDI have a full-service tool room on site and we have developed a reputation as a quality provider of new molds at prices that stand up well when compared with ovezrseas. While we build most of our molds in-house, we also have relationships with domestic and overseas supplier which we utilize when circumstances require. We will fully guarantee all molds that we built in-house and domestically.

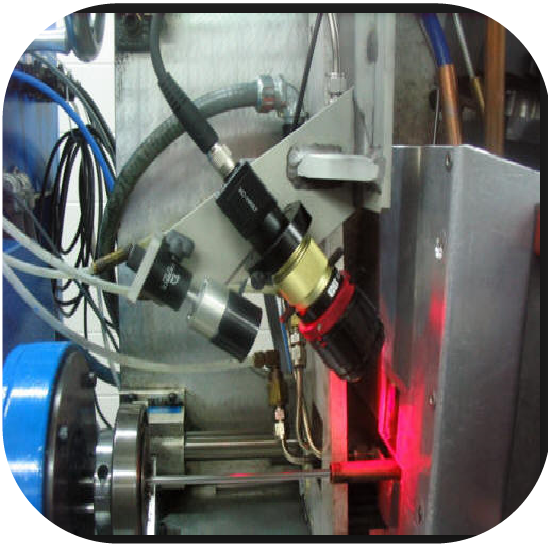

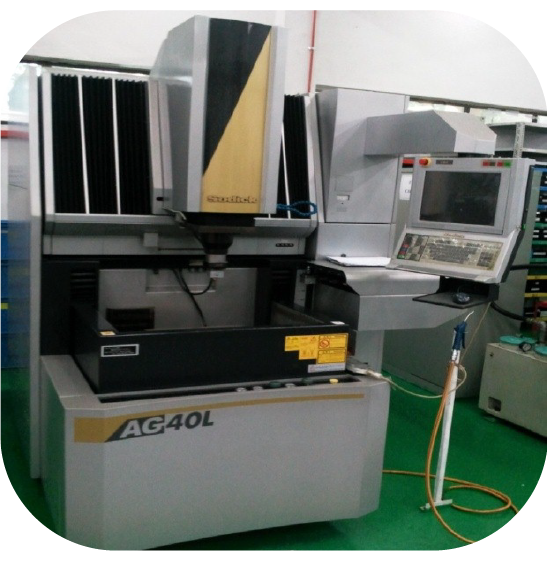

We can produce single & multi-cavity molds, over molds, insert molds, and as well as rotary-table mold and hot runners. We have extensive machining capabilities including High Speed CNC milling, CNC EDM, wire EDM, grinding, lathe, and 3R electrode clamping system that allow us to produce precision tooling from P-20 tool steel, to hardened steel, depending on the part production volume and application.

Molding Machine

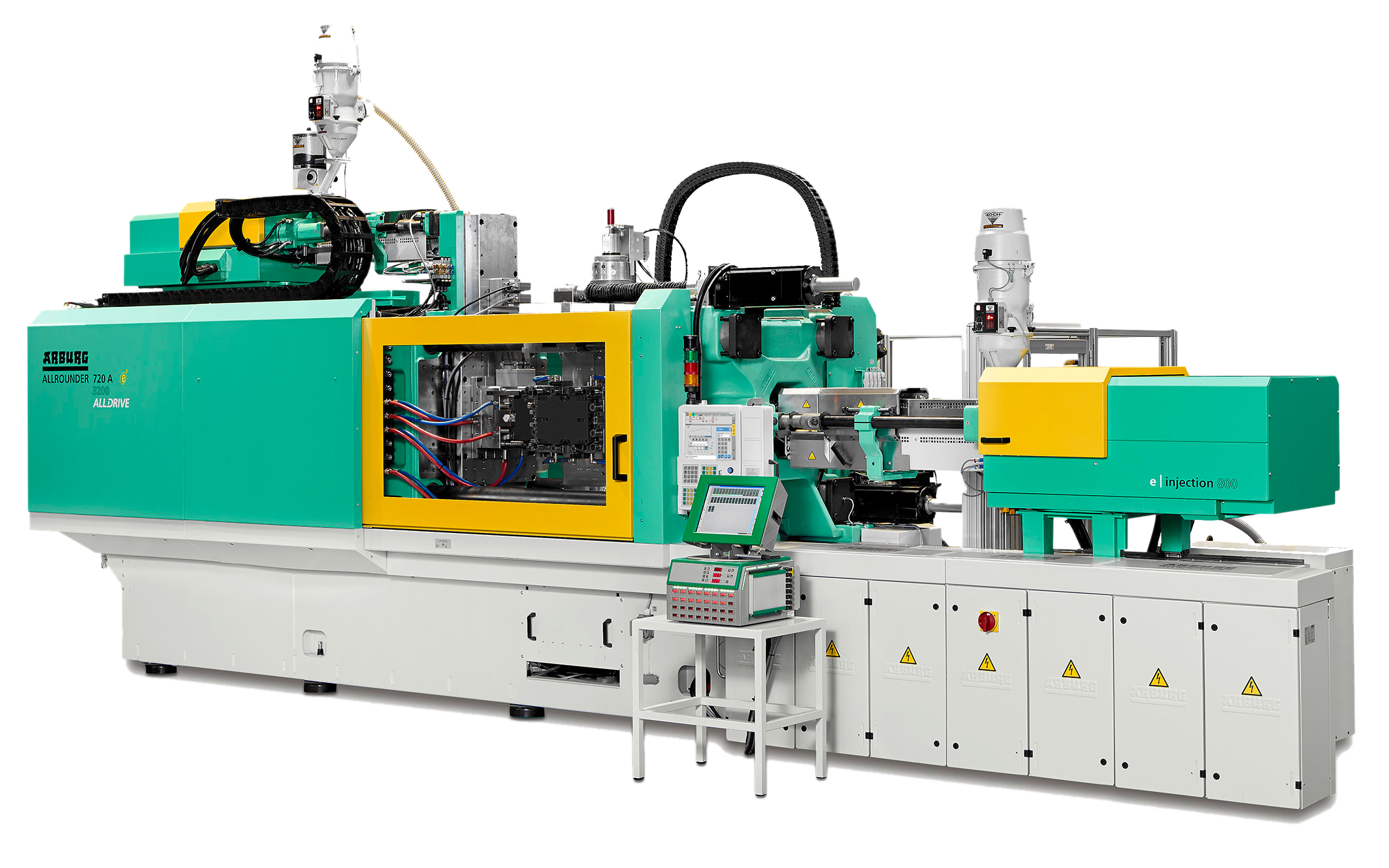

Millions of dollars has invested in purchasing best-in-class equipment. PDI has approximately 60 injection molding machines that range from 25 tons to 600 tons of clamping pressure. From micro precision components to large tonnage parts, PDI has the right equipment for your plastic products. Our next investment in clean room molding equipment will create greater efficiency and better control. What does it mean for our customer? Reliable quality at a competitive price.

PDI offers not just general molding services, instead, we have two-material molding machine for both core-rotation & insert rotation, automated robot arm system, vertical molding machine, All-rounder injection machine and also insert molding. With PDI’s controlled ambient production floor, quality is assured. PDI provides a solution on identifying & eliminating waste with our Quick change over system. This system allowed us to shorten

Added value- secondary operations

As one of the few one-stop solution plastic injection molding service provider, our comprehensive secondary operations and assembly scope enhance your plastic injection molding component or part providing you with complete product from start to finish. Our machines can perform any machining task on plastic including tempos printing, Spraying, Silkscreen, Heat Staking, Assembly Conveyor Line, Ultrasonic Welding, and press jig to your specifications and needs.

Silk Screening

Automated Spraying

Tampo Printing

Ultrasonic Welding

Heat Staking

Assembly Conveyor Line