Functional Finishing and Value-Added Integration

Precision-Driven Development Areas

From concept to execution, we focus on excellence in every aspect of our specialized fields.

Precision Finishing Capabilities

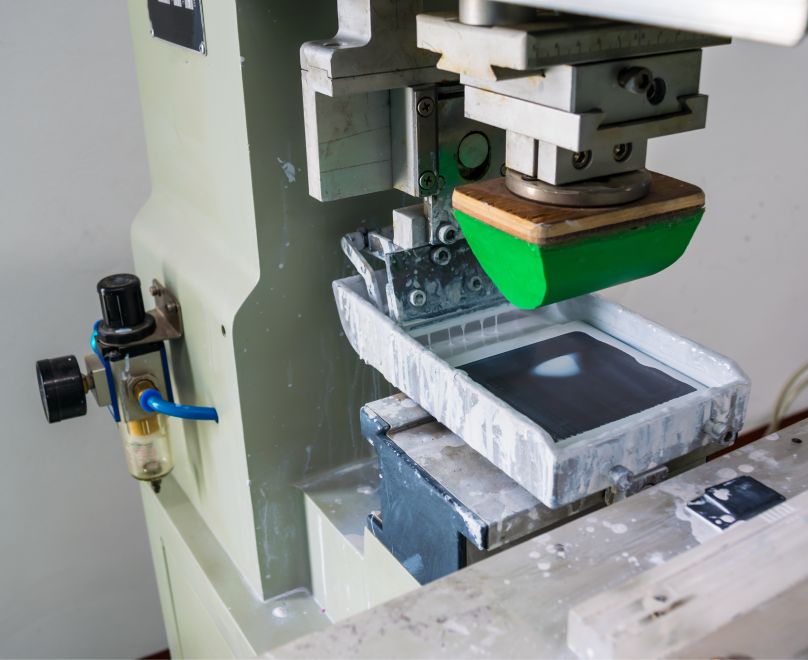

Pad and Screen Printing

Ultrasonic Welding and Heat Staking

Laser Marking and Traceability

Surface and Cosmetic Validation

Flexible Setup and Efficiency

Functional, aesthetic, and reliable finishing — every part, production ready.

Each secondary process follows a structured validation and inspection routine to ensure consistent quality and performance. Dimensional, cosmetic, and adhesion results are documented for traceability and process control, supporting customer and regulatory compliance across all industries.

We collaborate with customers to optimize component design for downstream processes, ensuring smooth integration between molding and finishing operations. This approach minimizes manual handling, reduces defects, and enhances production efficiency.

Success Stories

Success Story 1

Cycle Time Reduction Through Scientific Moulding Optimization

Our R&D team conducted a full 14-segment scientific moulding optimization for a high-volume product line. As a result, we reduced the overall cycle time by 18%, while maintaining stable product quality. This led to a 12% increase in production efficiency and significant energy savings—delivering measurable cost benefits for the client.

Success Story 2

Extending Mould Life with Precision Parameter Tuning

By applying our advanced moulding parameter optimization framework, we identified stress points affecting mould longevity. Adjustments to pressure, cooling time, and injection velocity extended the tool life by 25%, reducing maintenance downtime and increasing the number of production shots per mould.

Success Story 3

Improving Machine Utilization with Data-Driven Optimization

One of our clients faced inconsistent output due to parameter drift. Our R&D engineers used optimization data to fine-tune machine settings and monitor key variables. As a result, machine utilization improved by 22%, product rejection rate dropped by 40%, and process repeatability was achieved across multiple shifts.

Finishing Excellence